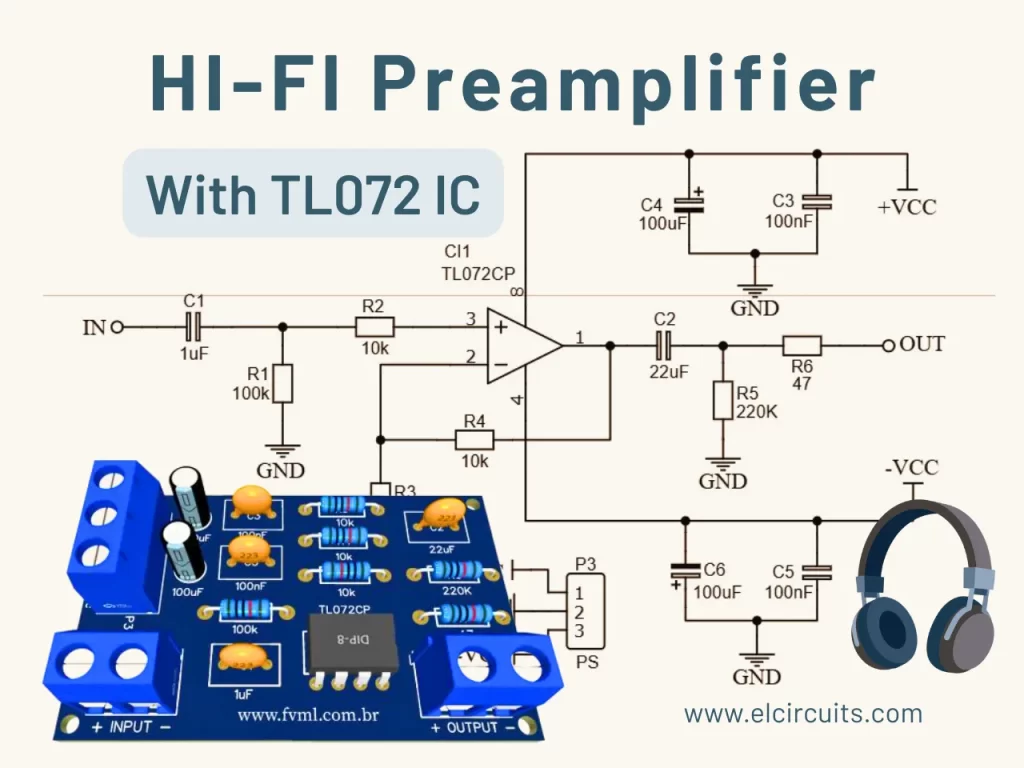

DIY TL072 Hi-Fi Preamp: Professional Build + PCB Layout

HI-FI Preamplifier Circuit with TL072 IC + PCB 🌐 You can read this article in: Português | Español Hello, electronics and high-quality audio enthusiasts! Today we will dive into the fascinating world of HI-FI preamplifiers with a simple yet extremely…

Português

Português Español

Español